PCB Exposure Box¶

| date: | June 10, 2010 |

|---|

This summer I finaly decided to start making my own PCBs. The preferred method for making PCBs at home is photolithography. The PCBs used have a layer of photo resist, which is exposed to a source of light through a mask. The exposed areas are then removed using a special developer chemical. Lastly, the PCB is dipped into the etchant and the copper is removed from the areas unprotected by the photoresist.

The first thing I needed was a light source. I decided to build a small box for exposing my PCBs.

3D modeling¶

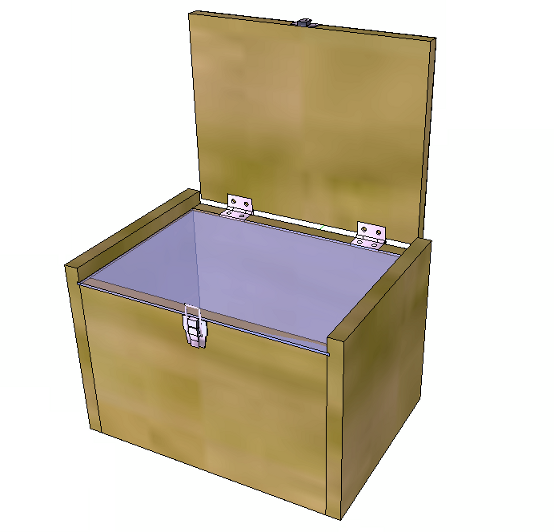

I began by creating a 3D model of the box usign Google Sketchup. This allowed me to spot any mistakes and tailor the design to suit my needs.

Bill of materials¶

I used the following parts to make this box:

- Chipboard

- Plexiglass for the window

- Fluorescent lamp

- Reflector from some old lamp

- IEC socket and cable

- Power switch

- Latch

- Pair of hinges

- Sponge cloth

- Screws, glue

Results¶

Below is the picture of a test PCB. The safe limit of track width seems to be around 0.2-0.25mm. This could be influenced by the source of light. While experimenting with the timing, I got an impression that UV light could do a better job as it would allow reduced exposure times.

Track widths from top to bottom are:

- 1.27mm

- 0.64mm

- 0.38mm

- 0.25mm

- 0.20mm

- 0.15mm

- 0.10mm